| Sketch

| Model

| Render

| Sketch | Model | Render | Print

Design

Virtual modeling is an exciting area of design that has grown rapidly in recent years. The technology has become increasingly important in the design process, offering new and innovative solutions to age-old problems. One such technology is Gravity Sketch, a virtual modeling tool that allows designers to work in Virtual Reality. The software's innovative features and intuitive user interface enable designers to create intricate and complex designs quickly and efficiently, yielding high-quality results. By being able to create designs in 3D space of VR, Gravity Sketch helps designers visualize their ideas more accurately, leading to better communication, teamwork, and ultimately, better products. Thus, virtual modeling tools like Gravity Sketch have revolutionized the design process, providing designers with a more efficient, intuitive, and streamlined way to create compelling designs.

It all begins with an idea. Whether it’s turning your hobby into something more, exploring your own creativity, or sharing a creative project with the world, the benefits of 3D printing and rapid prototyping are numerous. These technologies allow for the creation of physical, tangible objects from digital designs, cutting down on manufacturing time and costs while enabling designers to quickly iterate and refine their ideas. The ability to hold and touch a physical object brings an added level of insight and understanding to the design process. Rather than relying solely on virtual images or computer simulations, designers can see how their creations will look and feel in the real world, making it easier to identify and solve design problems. Additionally, tangible models can be shared and tested with stakeholders, streamlining the approval process and ensuring that projects stay on track. Ultimately, 3D printing and rapid prototyping are changing the game for product development, simplifying the design process and improving the quality of the end products.

PLA

WOOD

RESIN

STEEL

Assembly

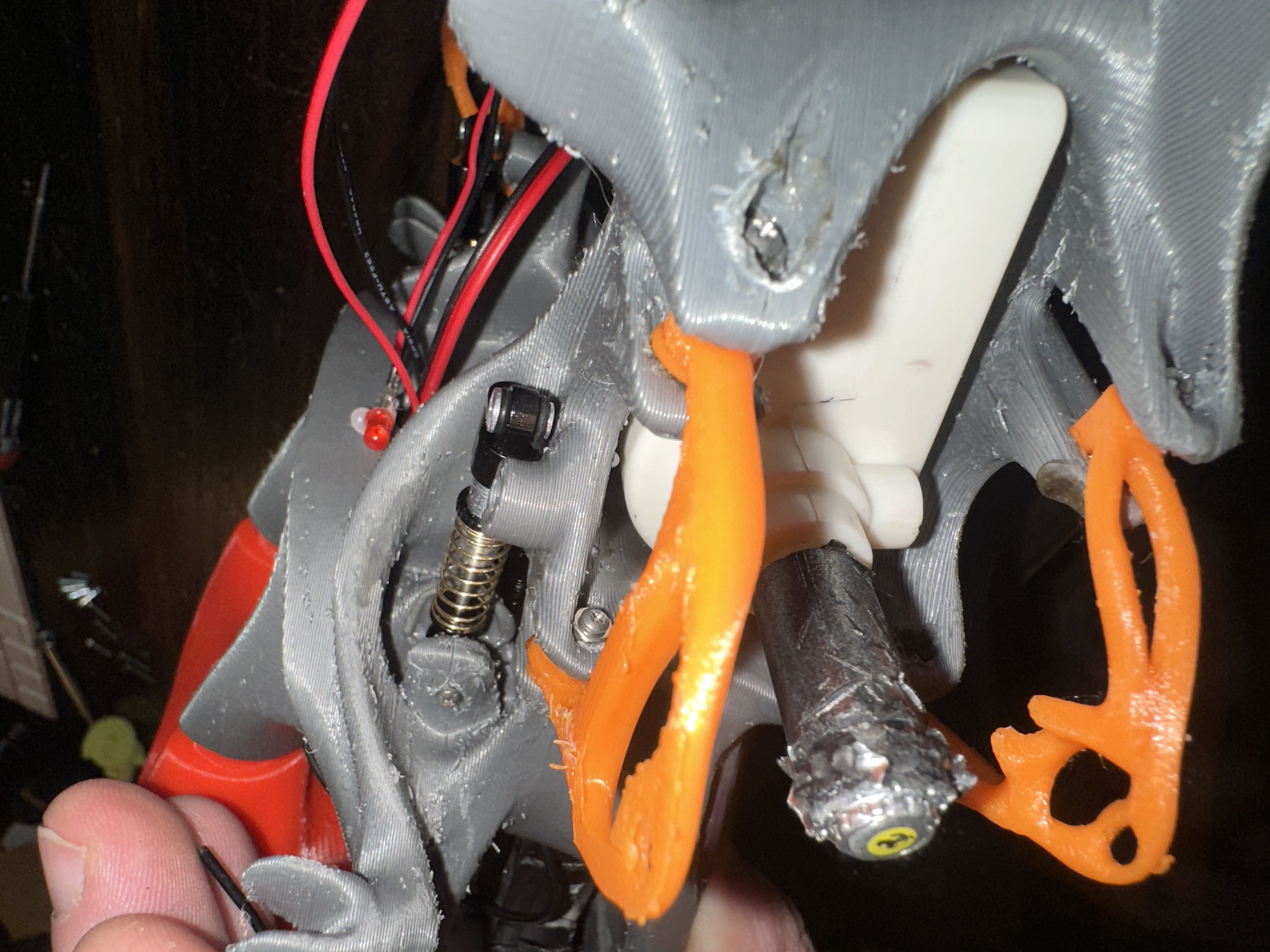

Assembling the final model can be a time-consuming and detail-oriented process. One important step is filling gaps with modeling paste to ensure a smooth and professional finish. It is also essential to find the correct fitment for all pieces to ensure they fit together seamlessly. This may require some trial and error and adjustments to the model. Once everything fits properly, sanding and painting can begin. Sanding helps to provide a smooth surface for paint to adhere to while also eliminating any imperfections in the model's surface. Painting is the finishing touch, and it's important to choose the correct colors and paint type for the desired effect. Finally, putting together the finishing touches, such as decals or added details, truly brings the model to life. Careful attention to each step in the process is crucial for creating a high-quality and stunning final product.

50% Completion

Heat Inserts

Heat Inserts are an essential component in various manufacturing processes where a secure and permanent threaded connection is needed. They are commonly used to reinforce threaded joints in plastic, metal, and composite materials, providing increased strength and durability. Heat inserts are typically made of brass, stainless steel, or titanium, and come in a variety of shapes and sizes to fit different applications. They are installed by heating the insert with a hot air gun or a soldering iron until they melt and bond with the material forming a secure and permanent threaded connection. Heat inserts are widely used in automotive, aerospace, medical, and electronics industries, among others, offering a reliable solution to improve the overall strength and life of the product.

Plastic Welding

Plastic welding is a process of joining two pieces of plastic material together through heating and melting. It is a practical and cost-effective alternative to traditional joining methods such as adhesive bonding, screwing or riveting. The process involves the use of a specialized plastic welding machine, which uses heat and pressure to fuse plastic parts together. The advantage of plastic welding is that it creates a strong, permanent bond that is resistant to pressure, heat, and chemicals. Plastic welding is commonly used in industries such as automotive, construction, plumbing, and manufacturing, where plastic parts are a vital component of their products. It is an eco-friendly process that reduces waste, and it is also a popular choice for repairing plastic items such as water tanks, kayaks, and car bumpers.

PLA Prototype

Prototyping with PLA filament is often considered the best starting point for 3D printing enthusiasts for several reasons.

Cost-Effective:

PLA filament is one of the more affordable options available in the market. Its lower cost makes it an ideal choice for beginners who are still refining their printing techniques and not ready to invest significantly in more expensive materials.

Ease of Use:

PLA is known for its ease of use. It doesn't require a heated bed, and it adheres well to different surfaces. This makes it user-friendly for those who are new to 3D printing.

Safety:

PLA is a biodegradable thermoplastic that is derived from renewable resources like corn starch or sugarcane. It emits no toxic fumes during printing, making it a safe option for prototyping in home or educational settings.

Wide Color Selection:

PLA filament comes in a wide range of colors, allowing for vibrant and visually appealing prototypes. This variety can be inspiring for beginners looking to explore the creative possibilities of 3D printing.

Good Print Quality:

PLA has good dimensional accuracy and stability, making it suitable for producing high-quality prototypes. Its ability to capture intricate details makes it a reliable choice for testing designs before moving on to more advanced materials.

Resin Prototype

Resin printing, also known as stereolithography or SLA printing, offers several advantages for prototyping in various industries.

High Precision: Resin printing enables the creation of intricate designs with high precision and fine details, making it ideal for prototyping complex geometries.

Smooth Surface Finish: The process results in prototypes with smooth surface finishes, reducing the need for extensive post-processing compared to other printing methods.

Diverse Material Options: Resin printing supports a wide range of materials with different properties, allowing for the prototyping of products that need specific characteristics like flexibility or transparency.

Speed and Efficiency: Resin printers can produce prototypes quickly, helping to speed up the design iteration process and accelerate product development timelines.

Cost-Effective for Small Batch Prototyping: While the initial investment in a resin printer may be higher, it can be cost-effective for small batch prototyping due to minimal material waste and lower labor costs.

Supports Complex Shapes: Resin printing can create prototypes with complex shapes that may be challenging or impossible to achieve using traditional manufacturing methods.

Minimal Post-Processing: The prototypes produced using resin printing typically require less post-processing, saving time and effort in refining the final product.

Improved Accuracy: With the precise layer-by-layer printing process, resin printing offers improved accuracy in replicating the original design, ensuring that the prototype closely matches the final product.

Overall, resin printing offers significant advantages for prototyping, making it a valuable tool for designers, engineers, and manufacturers looking to iterate quickly and efficiently on their product concepts.

Public Feedback

Beginning with the end in mind

Starting a project or setting a goal with the end result clearly defined provides a sense of direction and purpose. When you begin with the end in mind, you create a roadmap that guides your actions and decisions. This approach helps in maintaining focus, prioritizing tasks, and staying motivated throughout the journey. By visualizing the desired outcome from the beginning, you are better equipped to make choices that align with your ultimate goal, increasing the chances of success and reducing the likelihood of veering off course.

Advantages of Market Research

Market research plays a crucial role in helping businesses understand their target audience, industry trends, and competitive landscape. By conducting thorough market research, companies can gather valuable insights that aid in making informed decisions. Some advantages of market research include:

Identifying opportunities: Market research helps businesses uncover untapped market segments, emerging trends, and customer needs, allowing them to capitalize on new opportunities for growth.

Mitigating risks: By analyzing market data and consumer behavior, companies can reduce risks associated with product launches, marketing campaigns, and business expansions.

Strategic planning: Market research provides valuable data for developing strategic plans, setting realistic goals, and allocating resources effectively to achieve desired outcomes.

Understanding customers: Through market research, companies gain insights into customer preferences, purchasing behavior, and feedback, enabling them to tailor products and services to meet consumer demands.

Competitive advantage: By staying informed about competitors and market dynamics, businesses can differentiate themselves, innovate proactively, and maintain a competitive edge in the industry.

Makevention

Bloomington, IN. August 2023

Makevention in Bloomington, Indiana

Makevention in Bloomington, Indiana is an annual event that celebrates creativity, innovation, and craftsmanship within the community. Held every August, this event brings together makers, tinkerers, artists, and technology enthusiasts to showcase their projects, share knowledge, and inspire others.

Attendees can expect a diverse range of exhibits, workshops, and demonstrations that cover topics such as electronics, woodworking, robotics, 3D printing, and more. Whether you're a seasoned maker or just curious about DIY culture, Makevention offers something for everyone.

In addition to the hands-on activities, Makevention provides a platform for local artisans and small businesses to showcase their products and services, fostering a sense of community and supporting the maker movement in Bloomington.

Makevention was the first public event to expose the AMR XP-1. The painted model was displayed as a ready to assemble kit atop a poster reading “Build-A-Car”. It received tremendous attention. Many came to assemble. One kid did it in under 10 mins. The doors were broken during one of the assemblies. It highlighted a shear point. That area of the door was thickened to resist another drop.

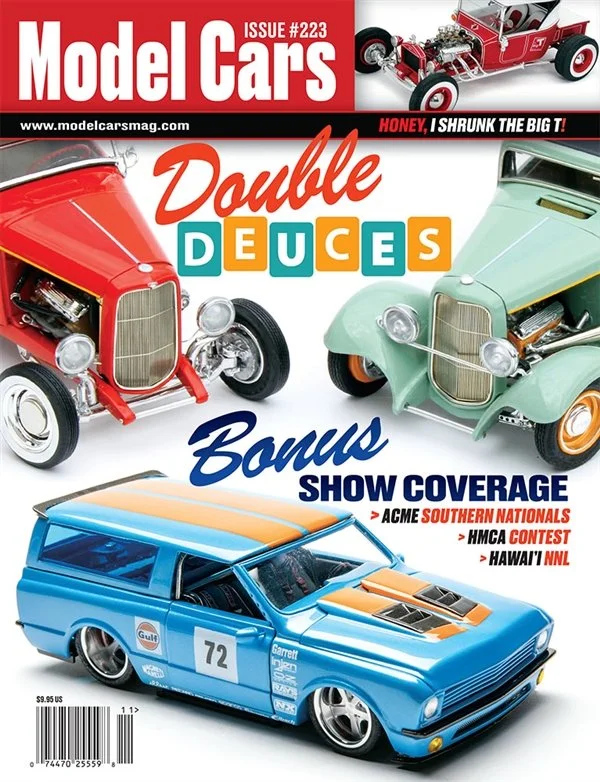

2023 ACME Southern Nationals

Atlanta Car Model Enthusiasts Cartersville, GA. Oct. 2023

100 Years at Le Mans

The Acme Southern Nationals Model Builders Competition is an annual NNL - Style event that showcases the craftsmanship and creativity of model builders from the southern region of America. Participants from various backgrounds and ages gather to display their meticulously crafted models, ranging from classic cars and airplanes to futuristic spacecraft and architectural wonders. Attendees evaluate each entry based on criteria such as attention to detail, accuracy, and overall presentation. There are categories for each type of build. 3D Printing has been recently added. Trophies are presented for Top Ten and Best in Show.

This event had over 100 vendor tables and over 900 models on display entered by builders from 24 states and Canada. Three special themes were featured, 100 Years at Le Mans, Corvette, and NASCAR. The tables were packed with 1/24 and 1/25 models. In struts Andrew Michael Robertson with a huge cardboard box. The 1:10 scale model dwarfed the other models. Luckily there was just enough space to accommodate the model.

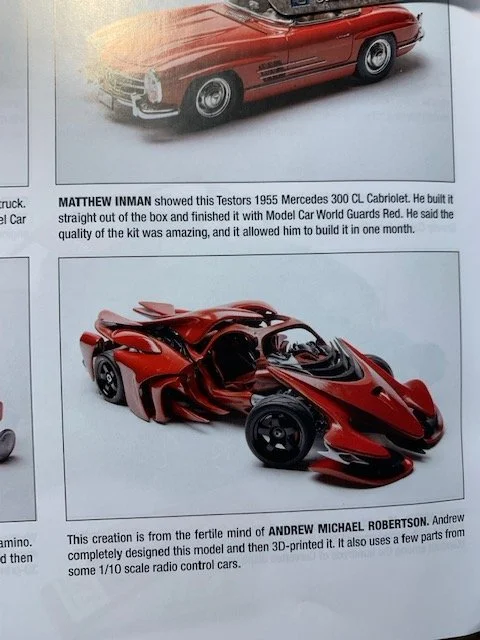

The XP-1 didn't receive an award that day but the feedback was more valuable. Plus a photographer shooting for Model Cars magazine was set up in the corner…

Model Cars Magazine

Issue #223 Page 38

Model Cars Magazine is dedicated to the art and hobby of model car building. Each feature-packed issue contains helpful articles and items of interest, including kit reviews, new product announcements, “how-to” tutorials, build breakdowns, industry news and interviews, and much more.

A photographer was covering the ACME show. He had a white backdrop scene set up on a table. Modelers were taking turns getting their cars shot for a chance to be included in the publication. The photographer kindly explained he had no say in the selection process and wished us all good luck. When I sat the XP-1 he looked at me excitedly and said, “What is it?” I explained and wrote everything down for him to reference. He snapped off a couple shots, one 3/4 passenger view ended up included in coverage of the event.

Issue #223 was shipped in February. By March most readers had received their copy. By Mid-March I had people trying to find me online.

It is an honor to have your work included in the publication. Thank you Model Cars Magazine.

To subscribe head over to www.modelcarsmag.com

Finished Product

The Final Product is 3D Printed in ABS-Like Resin. ABS-Like Resin is much more flexible and resistant to breaking than standard photopolymer Resin. The result is an end user quality kit, fun for all ages!